It was exciting to get such deep insights into the supply chain, but we also realised: We don’t really fit the mold. Our vision to make all fashion circular, including our zero plastic tolerance and organic dyeing only-policy, differs from what factories are used to. It’s outside their usual profile.

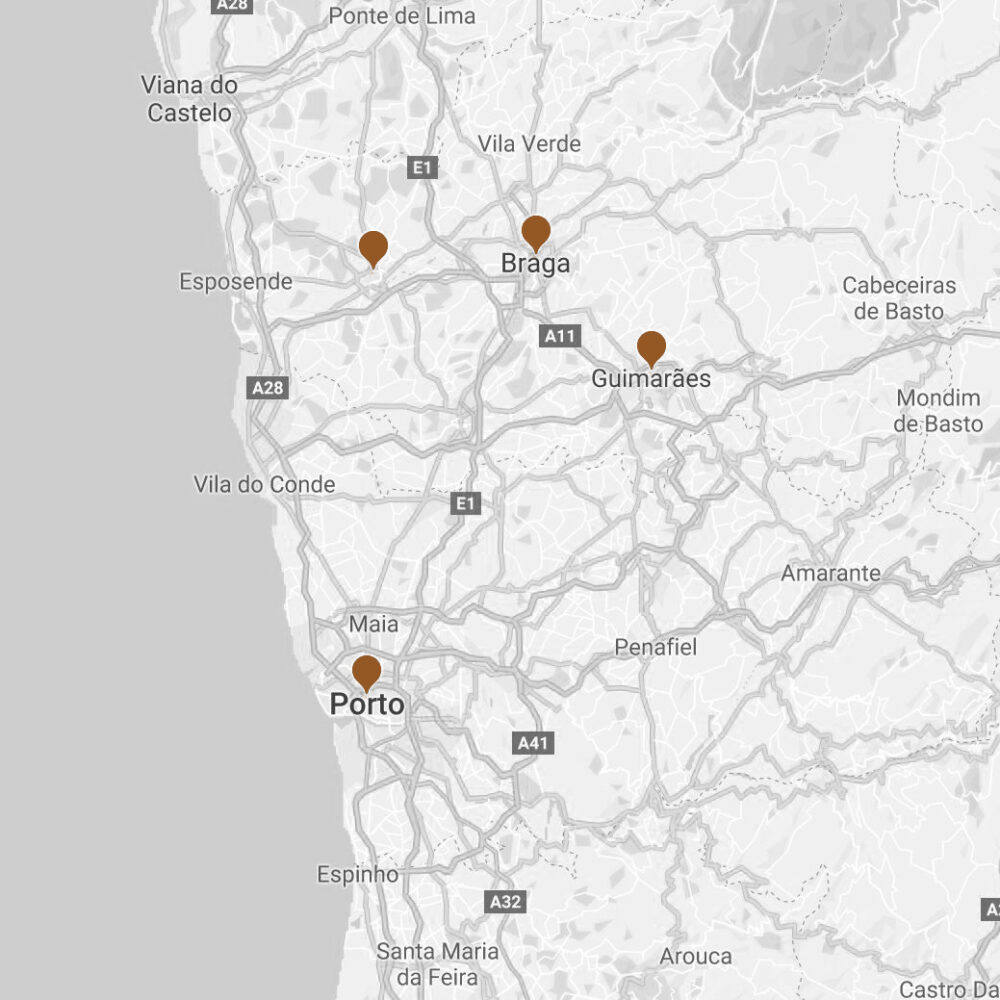

However, this only confirmed to us that we are on the right track. The whole industry needs transformation – and by accustoming factory owners with our circular ideas we’re a driving force for change. Our trip to Portugal made us optimistic: There are lots of experienced craftsmen and passionate textile entrepreneurs, who share our values and are excited to make change happen. In the halls of Porto’s factories, we’ve discovered some promising innovations that we can already implement in the short term. Together, we can make the T-Shirt circular – step by step. Stay tuned for updates!